Sediment and grease separators with reinforced concrete tanks according to the MSZ EN 1825 standard. Wastewater containing a considerable proportion of grease in a non-separable form (i.e. emulsified) from applications such as dairy, cheese, making and fish processing or from distribution points having only dish-washing facilities, or from „wet waste compactors”, will only be effectively treated in grease separators under certain conditions. The wastewater may require further treatment.

Applications where the discharged wastewater contains solids that are quick to purify (e.g. the fish industry) do not require a sludge trap but the grease separator shall be fitted with a strainer or screening device fitted on the inlet side to retain coarse solids. Any retained solids should be removed, and the separator thoroughly flushed with clean water before operational intervals to prevent putrefaction.

The function of the equipment is to separate mud/sediment and grease from sewage/wastewater polluted by animal/vegetable oil/grease before submitting into the public sewage system. It must be avoided to install a sewage pump before the separator equipment if the installation of pumps cannot be avoided, a pump operating on volumetric displacement principle should be used.

Sedimentation and grease-separator equipment retains material as by its function (drift, buoyant grease/oil derivatives) separating them from water. The equipment is not applicable to clean communal (public) sewage! It does not neutralize, decompose, or reduce the number of contaminants in separated material, it does not reduce the quantity of contamination in any way, it stores them only, and regularly must be removed from equipment.

The precondition of effective operation is systematic supervision and maintenance. Equipment shall be supervised at least once monthly.

Please ensure that quantity of sediment and retained grease may not exceed the capacity of separating/retaining compartments. In case of longer operational standstill, it is recommended to empty the equipment. Damages resulting from lack of maintenance are the responsibility of the operator! Equipment is made of reinforced concrete and the process units were made of stainless steel, polyethene or polypropylene.

Equipment operating on the principle of physical-components-separation can only operate if they are filled with water, it is the resting water in which sedimentation or floating-up of buoyant contaminants may happen. In separators, mud-compartment serves to catch sediment material. Buoyant material is retained by a deflector and by the position of the outlet pipe. In the separating chamber, considerably wider than the sewage pipe itself, the velocity of flow is decreased, consequently, sedimentation of material becomes possible. Outgoing water from equipment to sewage is led across a siphon pipe, which pipe takes out pre-cleaned water from the bottom of the tank. The outlet pipe is equipped with a cap on its top; by removing that cap the outgoing water may be sampled. Removal of accumulated grease can be done time to time across a manhole.

To avoid give-off of unpleasant smell to surroundings the manufacturer is ready to produce the equipment with smell-proof manhole-cover (for special order).

- cleaning capacity: 2-15 l/s

- easy installation

- high loadability

- monthly supervision is needed

- equipment is made of reinforced concrete

- process units is of stainless steel, polyethene or polypropylene

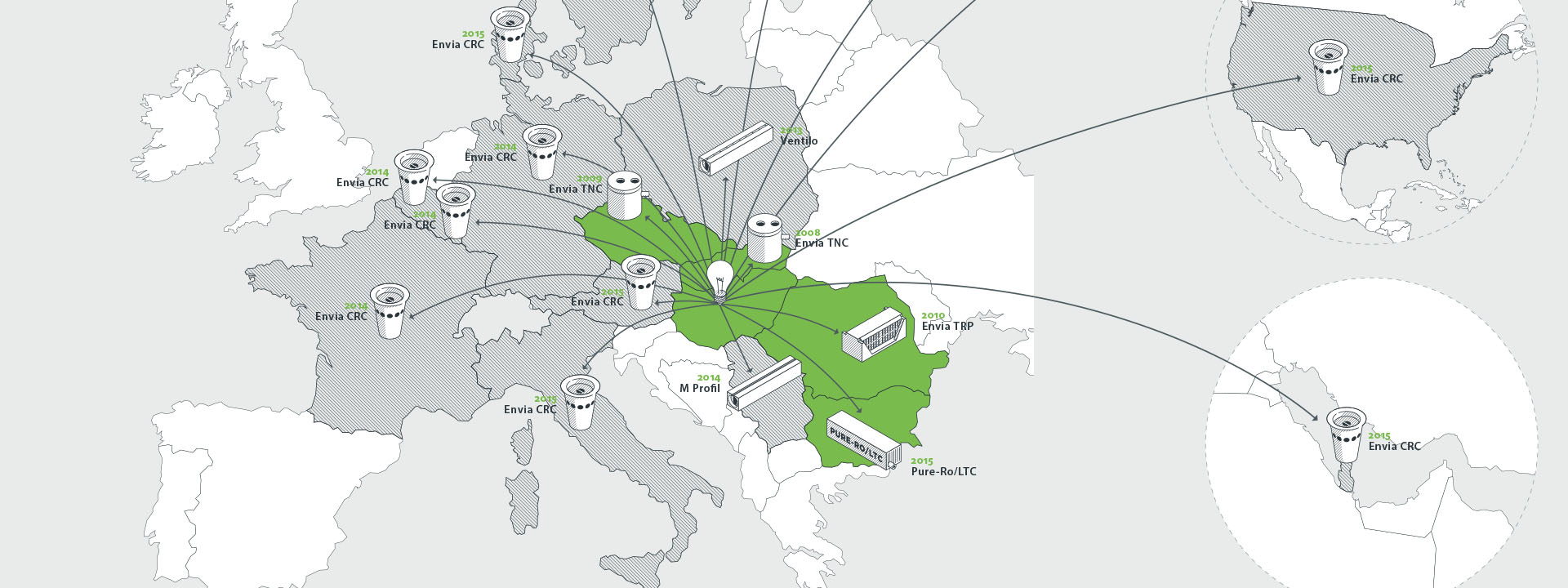

Fields of application

- sediment and grease separation

- compulsory use in oily or greasy wastewater

- canteen, hotel restaurants, slaughter houses and other meat processing plants

- food processing companies

Advantages of the product

- accommodated to the actual EU wastewater regulation

- retains sediment and floating grease and oil derivative as intended

- can be installed under motorways

Technical data

- physical phase separation

- operates in a water filled state

- supernatants are retained due to the position of the drain pipe

- separate sludge trap is operated through manholes

- odor-proof covers can be installed easy to install

Key benefits

- easy to install

- can be placed in groundwater

- by sizing anchoring