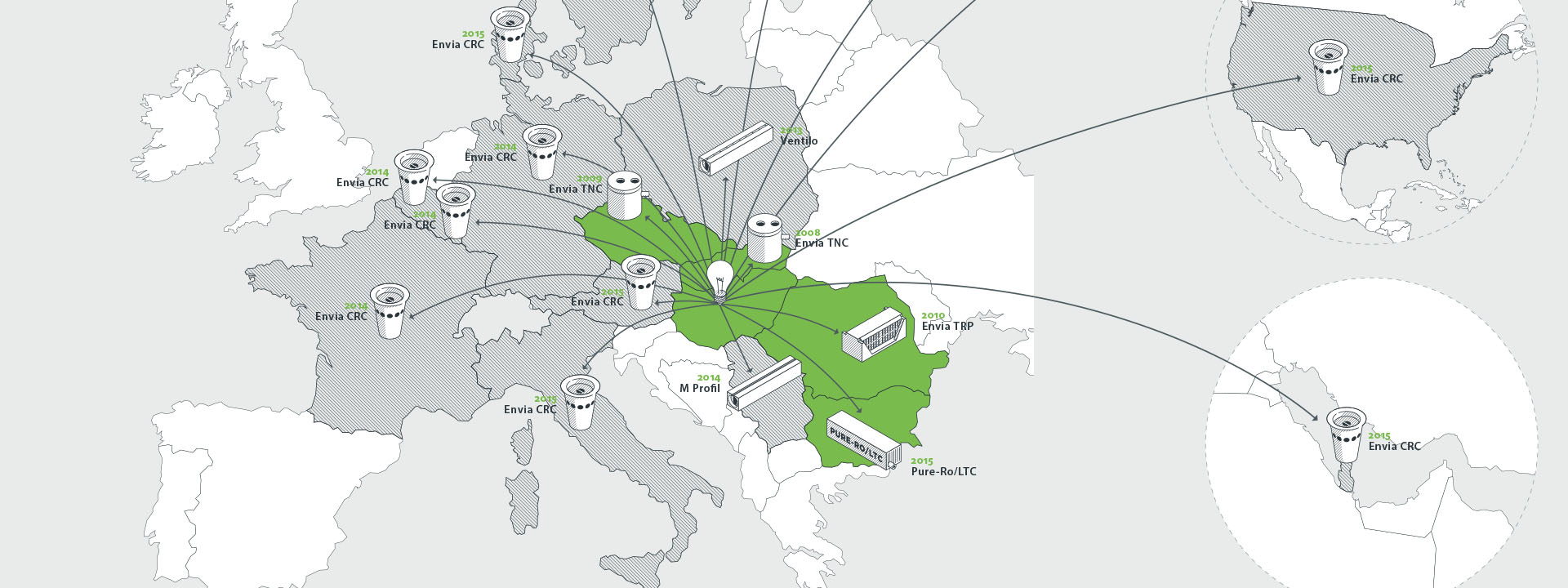

Ductile iron pipe systems, produced by Tiroler Rohre GmbH (TRM) in Hall in Tirol/Austria, are uniquely suited for no-dig (trenchless) technology. These pipes are widely used in drinking water and sewerage networks. Several external and internal coatings, valves and fittings are also available for the product family.

Ductile iron pipes are easy to install, they can be used up to 100 bar operating pressures. With FM Global certification the pipes are a suitable solution for fire-extinguishing pipes as well.

Cast iron, an alloy of iron, carbon and silicon, and ways of processing it have been familiar to mankind since early times. The first gray castiron pipes were produced more than 500 years ago and were used mainly for transporting drinking water and water for utilitarian purposes. In the early 20th century, metallurgists discovered that graphite which separated out in spheroidal form allowed stronger pipes to be manufactured.

The spheroidal form of graphite was first observed when elements such as cerium, lithium and barium were added to molten iron, but in the middle of the last century, industrial processes were developed for treating the molten iron with magnesium, because magnesium did the same thing but was very much easier and cheaper to obtain than these elements. That was the hour of birth of ductile cast iron.

Fire-extinguishing systems

A fire-extinguishing system is a technical system which is constantly on standby and which tackles a fire with an extinguishing agent. It is used for protecting and saving human lives. Wherever human lives are protected, attention must be paid to redundancy, safety and margins. Ductile iron extinguishing water pipe is non-combustible, absorbs stresses and provides sufficient extinguishing water in the event of an emergency. FM approval is confirmation that our ductile iron pipes meet the requirements of state-of-the-art, reliable fire-extinguishing systems.

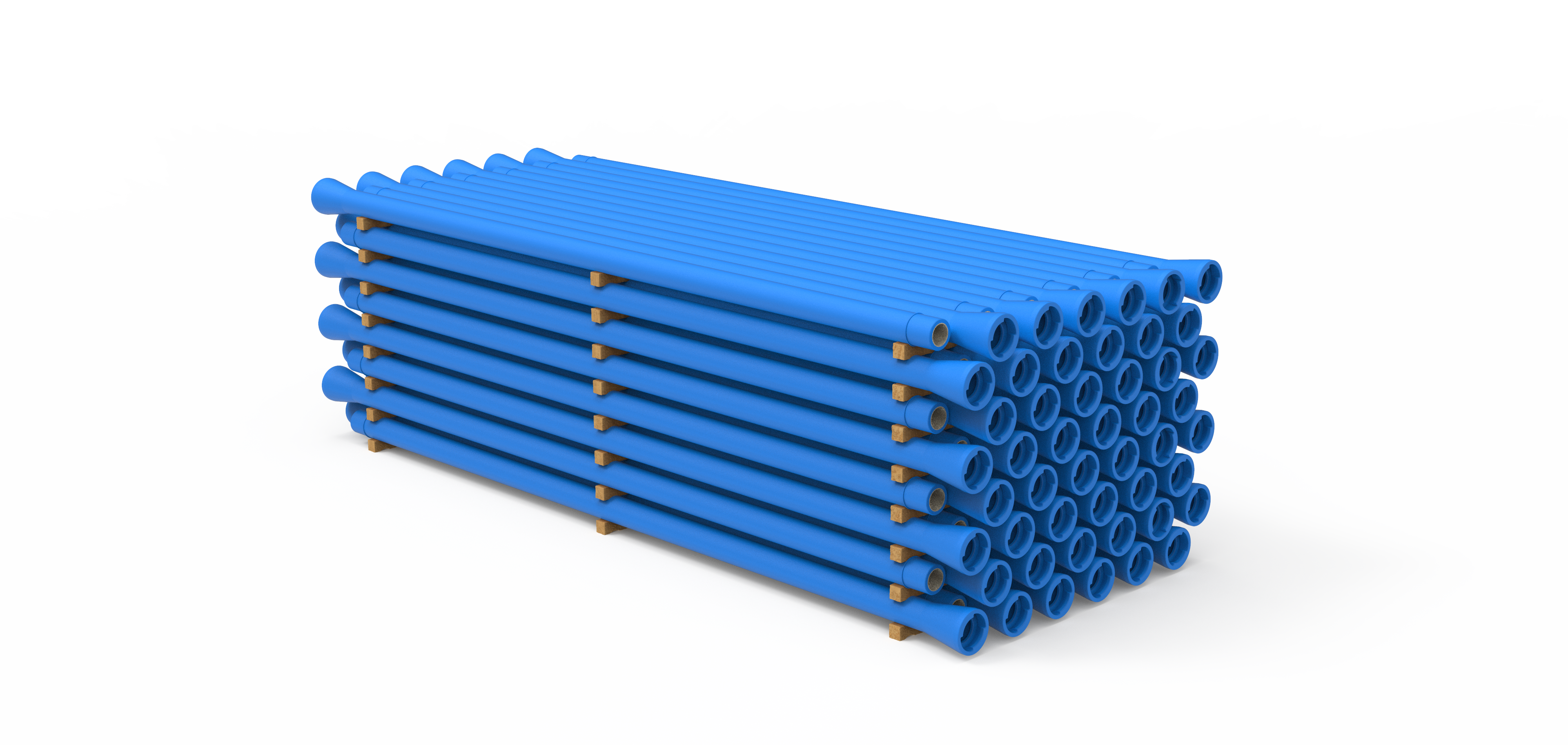

Trenchless technology

When building new pipe networks or renovating existing ones, conventional open pipe trenches in urban areas often push the limits of what is feasible. In order to avoid large-scale traffic obstructions in conurbations, trenchless pipe construction methods began to be developed 30 years ago. Benefits of laying ductile iron pipes without trenches: the very short assembly times, it enables small start and target pits. Single pipe installation means no elongated construction-site installation areas are necessary. Spherical graphite cast iron pipes can be fastened with quick-release tensile joints and adequate external surface protection (thanks to two developments of TRM VRS-T tensile joints and cement mortar coated (ZMU) ductil iron pipe) the unexplored reconstruction is fully available, if the given drinking water line can be renewed by keeping the original route in the DN 80-1000 mm size range, 25-30% cost reduction and time savings can be achieved with no no-dig technology comparing to the traditional, open-air technology especially in urban, high traffic environment.

- Short transport distances

- Made from recycled material

- Environmentally-friendly production

- High safety margins (type-tested products according to EN 545)

- Environmental protection, no organic material

- Low maintenance and servicing costs with a long service life

Fields of application

- drinking water and sewage drainage

- uniquely suited for pipe laying without uncovering TRM pipe systems are also a flexible and reliable solution for fire water systems

Advantages of the product

- Reliable, economical and ecological water supply

- Hygienic, safe transport of drinking water as a nutritional resource with no diffusion losses

- Decades of tried-and-tested use

- High water-supply security

- Low reinvestment costs due to long service life

- Resource conservation thanks to quick and simple installation

- A wide range of products for the ideal pipe system

- Minimal maintenance required

- Simple installation

- Root-resistant material

- Sustainable production

Key benefits

- long service life

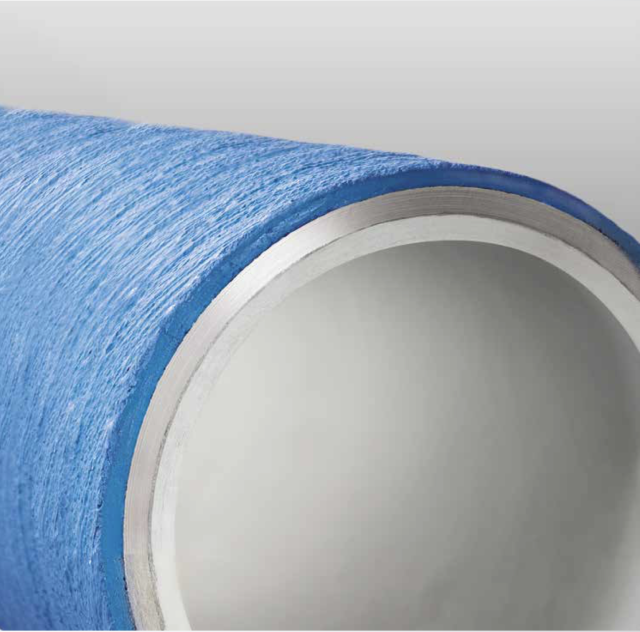

- external and internal coatings

- available in different load classes to suit the conditions

- high technical quality (e.g. high corrosion resistance)

- economy (e.g. due to fast and cost-effective installation)

- environmentally friendly (with a life expectancy of approx. 100 years)

- quick and easy assembly

- pipe laying without uncovering

Technical data

- VRS®-T joint (fully sealed, movable and with restrained joints, can be bent up to 5°)

- Robust

- Active and passive corrosion protection

- Diffusion-resistant

- Resistant to root penetration

- Fire-resistant

- Resistant to aging

- Lining approved for food-hygiene standards