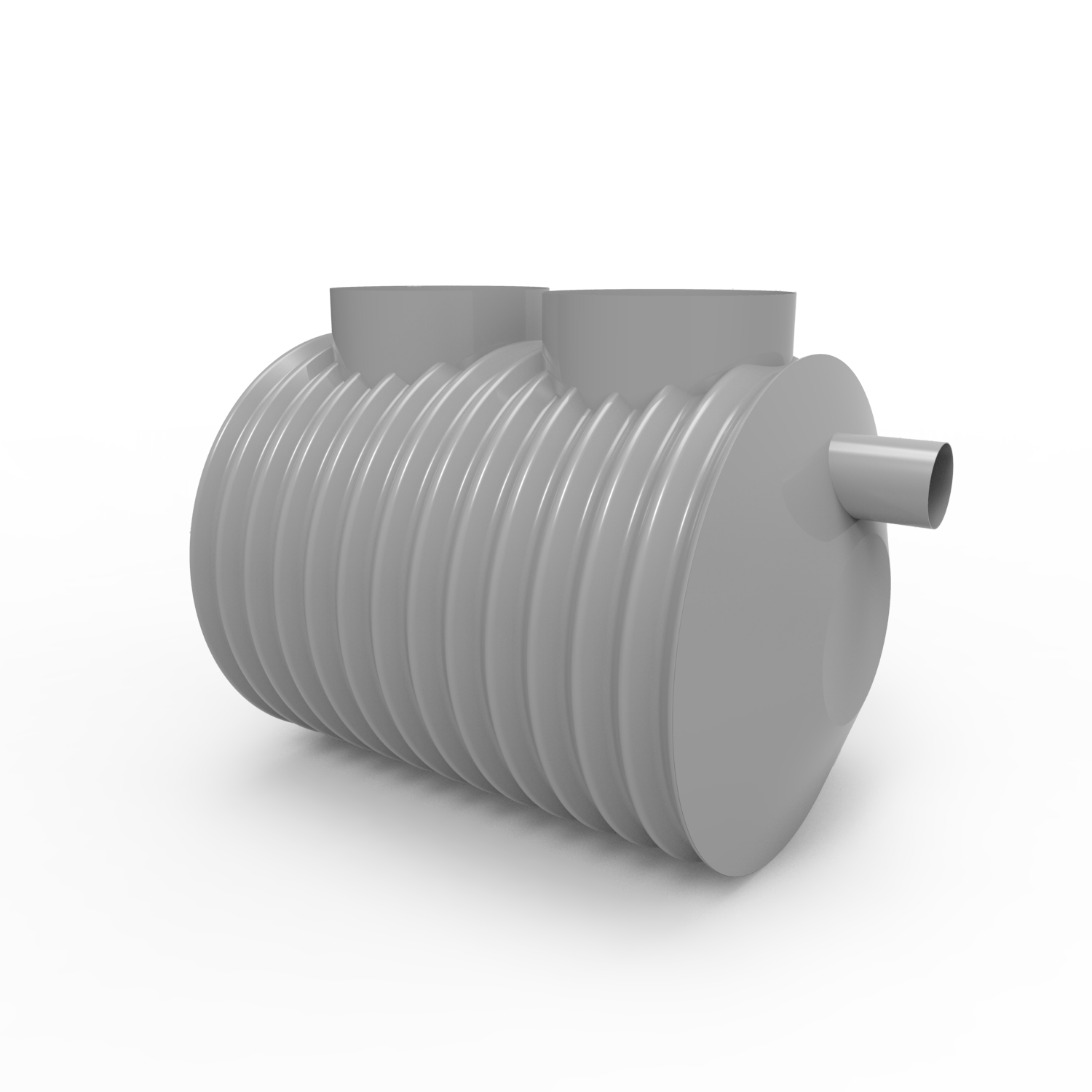

Combining the main advantages of plastic and concrete tanks, we have created the ENVIA TNP steel oil separator family. Steel equipment weighs only 5-6% of the weight of concrete equipment. Due to the weight and size of the product, it is easy to transport and easy to install. Corrugated steel pipes have been used as a passage in highways for decades because, despite their thin wall thickness, their corrugated spiral structure provides maximum load capacity. Our oil separators are also made of spiral steel pipes with such a spiral structure, so the equipment becomes load-bearing immediately after installation and refilling. We provide our steel tank with a 700 mg / m2 zinc coating and an exterior-interior epoxy coating, which makes it one of the most durable products on the market. In the case of spheroidal graphite cast iron pipes used in drinking water supply networks, the pipes fully comply with the requirements of zinc (300 mg / m2) and epoxy coatings expectations. Due to the applied epoxy coating, the separation equipment is also fully resistant to possible electrocorrosion.

- Lightweight and durable

- Wide capacity range: 40-350 l/s

- 2 and 5 mg/l FOG

- Zinc coating

- epoxy protection

- Extra load capacity

- Easy transport

- Easy installation

Fields of application

- passage in highways

Advantages of the product

- steel equipment weighs only 5-6% of the weight of concrete equipment.

- it is easy to transport

- easy to install

Technical data

- Light and load-bearing structure

- Full size range up to 40-350 l / s

- 5 and 2 mg / l grease and oil limits

- 100x and 200x sludge traps

- For road load "A" Zinc + Epoxy coating

Key benefits

- 700 mg / m2 zinc coating and an exterior-interior epoxy coating

- most durable products on the market.

- fully comply with the requirements of zinc (300 mg / m2) and epoxy coatings requirements

- the separation equipment is also fully resistant to possible electrocorrosion