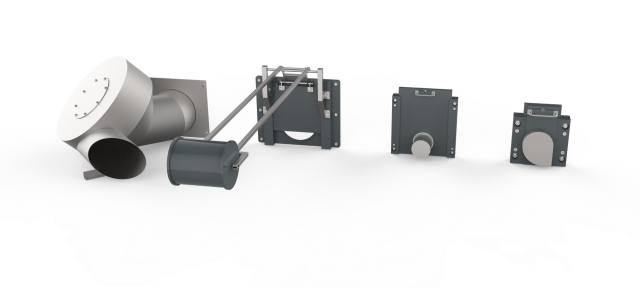

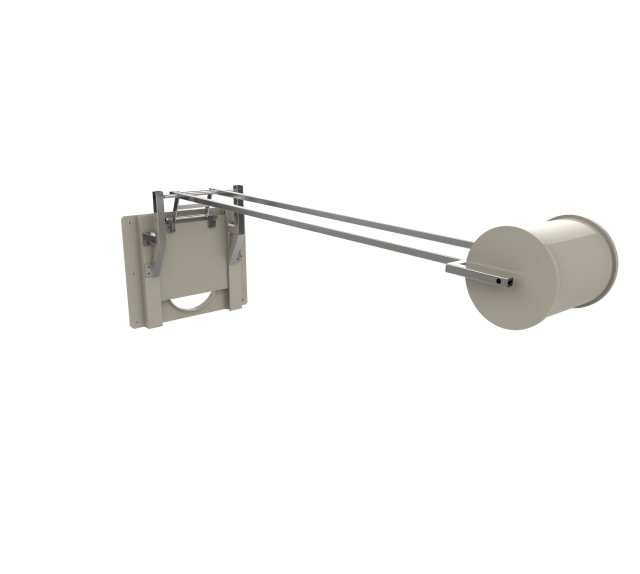

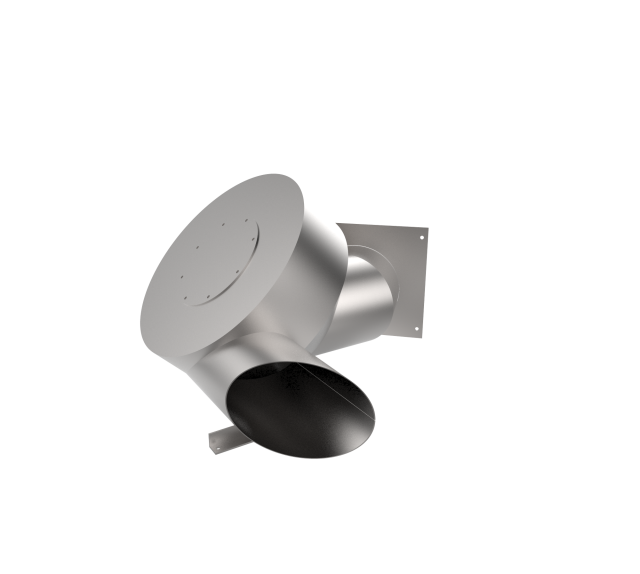

Vortex valves are used to regulate the flow, expressed by the speed of water flow in l / s. They are most often placed in the drainage area of the retention tanks and relief chambers. The valve consists of its own body, drain chamber and stabilizing mounting. The shape of the valve body ensures high pressure resistance of the device. The water flows tangentially into the body of the vortex valve, where a vortex flow is created. An aerated core is formed in the center of the vortex, which closes a large part of the outflow. Due to the generation of centrifugal force on the wall of the controller, the inflow is limited. Water flows from the valve body in the shape of a hollow jet. The drain is equipped with a replaceable screen, which can be easily adjusted to the required amount. The vortex valve is attached by mechanical anchors at the point of connection of the drain pipe to the inner vertical wall of the tank or by means of a reducing flange to another type of tank. The wall plate of the valve must cover the drain pipe over the entire area. The contact surfaces of the wall plate and the tank wall are sealed with polyurethane sealant.

- works without moving parts

- it wears minimally

- special maintenance is not needed

- checking the inlet in large amount of torrential rain

- corrosion resistant construction

- stainless steel

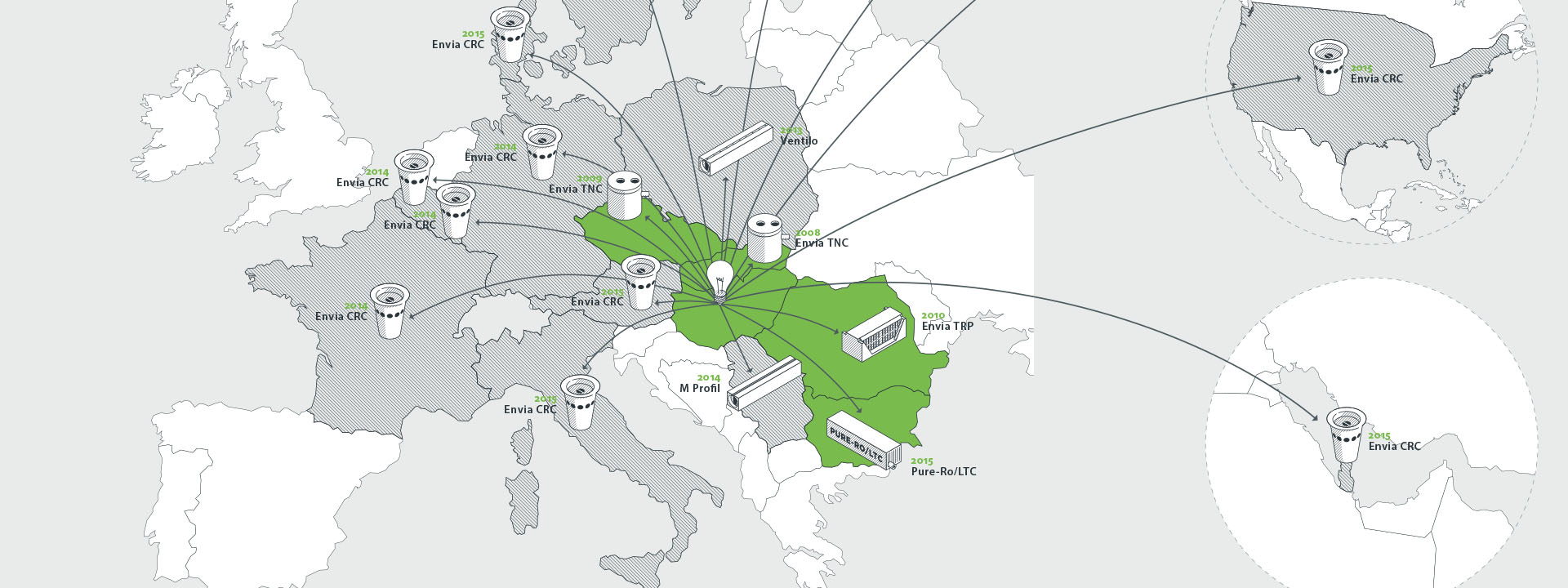

Fields of application

- to regulate the flow and express the speed of water flow in l / s

- placed in the drainage area of the retaining retention tanks and relief chambers

Advantages of the product

- vortex regulator

- reliable construction without moving parts

- corrosion resistant construction

- no moving parts

Technical data

- stainless steel AISI 304

- polyethylene (PE)

- polypropylene (PP)

- polyvinyl chloride (PVC)

- variable outflow parameters

- Q in l / s: 1 - 78 l / s, with an accuracy of ± 5%

- drain pipe range: DN 40 - 200 mm

Key benefits:

- long working life

- easy installation

- high wear resistance

- high reliability