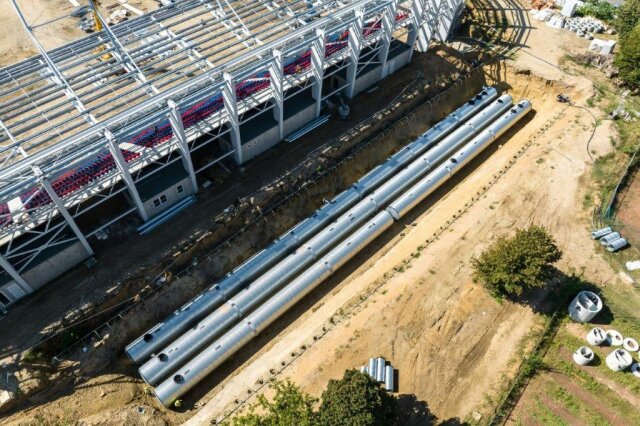

In Nyíregyháza (north-east part of Hungary), after the demolition of the former stadium, an 8,150-seat, 12,200 square metre facility with a 10,000 square metre central pitch will be built. The development is being carried out by Épkar Zrt. and Nyír-Wetland Generál Zrt. on behalf of the Ministry of Construction and Transport.

We supplied and installed rainwater storage tanks with a capacity of over 1000 m3 for the new Nyíregyháza stadium as a subcontractor. We manufactured and assembled the tanks, coordinated their installation and acted as the responsible technical manager.

For the project, we supplied:

- a 113 m3 reservoir tank,

- a 165 m3 flow-through rainwater reservoir to provide irrigation water,

- and a reservoir with a capacity of 814 m3 to retain rainwater.

The original tender for the 814 m3 storage tank was for a reinforced concrete structure, but the investors opted for spiral, galvanised steel tanks due to their economic efficiency, shorter installation time and long service life. The 165 m3 flow-through rainwater storage tank can meet both the 80 m3 daily water demand for track irrigation and the 70 m3 daily demand for the green areas on the property. This reservoir capacity is in addition to, and in addition to, the 810 m3 of delayed storage capacity that will be constructed in line with the track irrigation.

The products associated with the storage tanks have enabled easy and fast construction, with progress of around 120-150 metres per day, depending on the design.

In addition, moving is easy in relation to the reservoir capacity: even a rotary excavator can be used for shorter reaches.

The structure is load-bearing immediately after construction, with a load capacity corresponding to road load class A.

Equally important is the fact that there are no maintenance costs for the operator, with a service life of at least 50 years, depending on the PH of the soil. They added that, if the technical filling is constructed as specified, the pipe structure will not be susceptible to mechanical stresses.

Flexible cooperation was also key to the project. After the products had been manufactured and delivered to the site, our colleagues also carried out the watertight technological installation of the equipment. At the same time, the customer was responsible for the preparation of the technical filling according to specifications. After the installation, we provided the operators with information on the operation of the system.

Due to the nature of the work, it was necessary to work in coordination with many companies, which required a great deal of attention and a constructive, solution-oriented approach. In the Nyíregyháza project, too, win-win cooperation was a key factor, as the design and site layout had to be changed several times during the negotiations to ensure that the products to be manufactured were fully compliant with the modifications made during the utility design. In the end, we were able to meet the desired requirements in all cases.